Oil & Gas

Experts in Oil & Gas

MCAM Engineering Plastics are used in applications in all areas of the Oil, Gas & Industry, Engineering and Maintenance.

Key Benefits:

- High mechanical strength

- Chemical and corrosion resistant

- Materials operating in temperatures of -50ºF (-45.5ºC) to 480°F (250°C)

- Low weight compared to metal components

- Low coefficient of friction

- Low moisture absorption

- Excellent dimensional stability and quality

- Low coefficient of thermal expansion

- NORSOK M-710 (sour gas aging)

- Compliance for Ketron® PEEK stock shapes

Application:

✓ Pipeline systems (pipe in pipe spacers, pipe

✓ clamps, lined pipe, pipe collars)

✓ Subsea vehicles (thruster cowlings, bearing, seals)

✓ Lifting equipment (cable sheaves, hook blocks,

✓ bearing pads)

✓ Instrumentation (insulators, sensor protectors,

✓ guidance probes, connectors)

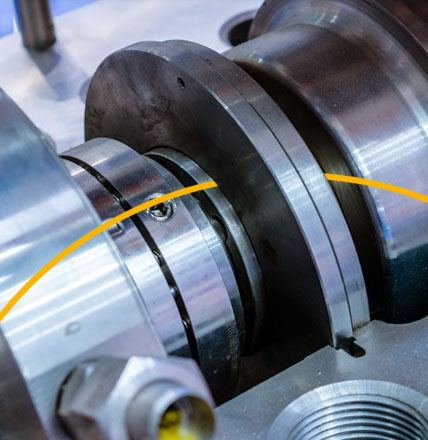

✓ Compressor, pump and valve components

✓ (seals, bearings and wear components,

✓ backup rings, lantern rings) Offshore equipment (bushings, slide pads)

✓ Large diameter bouy seal rings to over 16.4ft (5m)

Use of MCAM THERMOPLASTICS in Compressor , Pumps & Valves is to enhance

- Increased MTBR (Mean Time Between Rebuild)

- Increased MTBF (Meantime Between Failure)

- Reducing VOC Emissions

- Reduced Weight & Power Requirements

- Improved Chemical Resistance

- Reduce Seals Clearance

- Prolong Wear Life

- Improved Overall Performance & Efficiencies

PUMPS

Use of MCAM THERMOPLASTICS in Pumps

A PUMP is a machine that moves fluids (either liquids or gases) by mechanical action. Normally we think of PUMPS moving liquids (incompressible fluid)

- VANES • GEARS • ROTORS • IMPELLER • WASHERS •SHAFT SEALS • WEAR RINGS

- IMPELLER EYE • CASING-COVERS • SLEEVE-THRUST • BEARING CAGES

- CASE WEAR RINGS • LANTERN RINGS •LANTERN RESTRICTORS • LINE SHAFT BEARINGS

- THROAT & INTERSTAGE BUSHINGS

- ERTALYTE TX (PET-P), ERTACETAL (POM-C), TECHTRON PPS, PSGB Bearing Grade

- KETRON PEEK-1000, CA30, HPV, DURATRON PBI, PAI, FLUOROSINT 135 / HPV PTFE

VALVES

Use of MCAM THERMOPLASTICS in Valves

Valves regulate fluid flow by opening and closing. The moving parts of a valve and their actuators

are prime opportunities to improve performance through the use of advanced engineered thermoplastics.

- Valve Seats, Bushings, Body & Stem, Stem Seal, Soft Seals (Low Pressure)

- Hard Seals (High Pressure), Thrust Washers, Stem Seal Adaptor

- KETRON PEEK 1000, KETRON PEEK CA30, KETRON PEEK HPV, ERTALYTE TX PET-P

- NYLATRON GSMbr, TIVAR® 1000 UHMW-PE, DURATRON® PAI, FLUOROSINT® 207, 507, HPV

- TECHTRON PPS

COMPRESSORS

Use of MCAM THERMOPLASTICS in Compressor

A COMPRESSOR is a PUMP that compresses and moves compressible fluids…..aka GAS.

There are different types of compressors, some of which are✓ Positive Displacement (Reciprocating or Rotary),

✓ Dynamic (Centrifugal / Axial)

- Labyrinth Seals, Shaft Seals, Secondary Seals, Impeller Eye Seals

- Balance Piston Seals, Gas Seals

- KETRON PEEK CM, KETRON PEEK CA30

- DURATRON PAI, FLUOROSINT 500

Offshore & Onshore - Oil & Gas Equipment

Subsea

Exploratory

Highly engineered sonar and exploratory sensing equipment is used to locate, identify, define,and even map the ocean floor. Materials may require electrical insulation, impact resistance for toughness at cold temperatures, and the ability to handle extreme pressures at great depths.

- TIVAR® UHMW-PE

- Ertacetal® POM-C

- Nylatron® PA

- Ketron® PEEK

- Scanning

- Acoustic

- Sonar devices

- Remotely Operated Vehicles (ROV)

- Cameras

- Bumpers

- Connectors

- Crawlers

Above Water

Above the water structures, components, systems, and accompanying vessels are used for well drilling, exploration, or extraction of petroleum and natural gas. Necessary materials for these environments offer light weight, strength and stiffness, along with wear resistance and great corrosion resistance.

- TIVAR® UHMW-PE

- Nylatron® PA

- Techtron® PPS

- Fluorosint® PTFE

- Ketron® PEEK

- Work platforms

- Cable sheaves

- Slide pads

- Pipe handling

- Swivel joints

- Bend restrictions

- Winches

- Pipe-in-pipe spacers

- Seals

- Bearings

Down Hole

Down-hole equipment is anything that may go into the well for drilling, completion, or production enhancement of the flow from the underground reservoir. Components demand extreme strength and stiffness at various temperatures, along with the ability to resist degradation

from aggressive drilling fluids and down-hole chemicals.

- Ketron® PEEK

- Techtron® PPS

- Duratron® PAI

- Ertalyte® PET-P

- Back up rings

- Frac balls

- Frac plugs

- Insulators

- Connectors

- Couplers

- Flow meters